Non-wovens

Give your non-wovens the finishing touch they deserve

We offer you the best benefits

For any type of fiber

With various options in terms of hole amounts, hole sizes and hole distributions you can be sure to achieve the best and most efficient results for different fiber compositions and substances.

Uniform and perfect non-wovens

Our portfolio includes specially designed screens for de-airing and hydroentanglement (spunlacing). For the entanglement process we offer micro porous shells (MPS) that ensure uniform and perfect fabrics.

Take your hydro-jetting process to the next level

In a competitive market, as a non-woven manufacturer you must minimize downtime and optimize processes - but you also need to ensure production is sustainable. This useful guide helps you achieve the best possible output by comparing 3 MPS screens in the market:

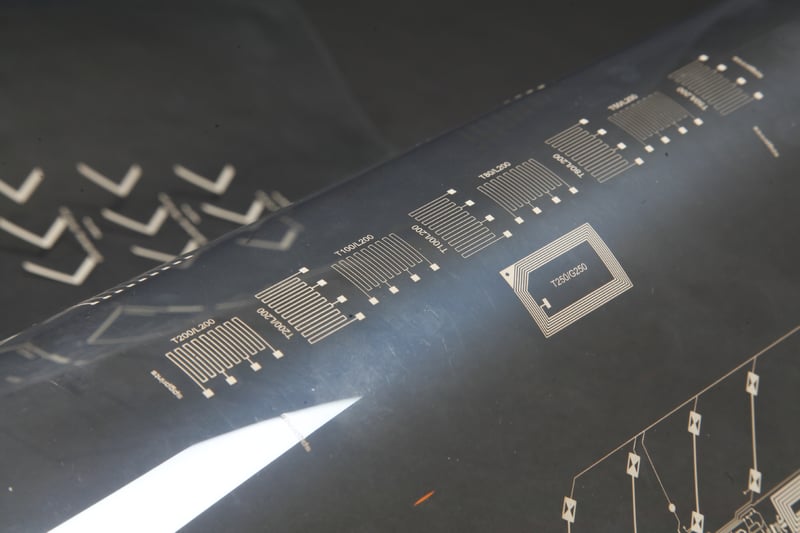

Micro perforated and ni-coated wire mesh

Enhanced precision & durability

These screens are ideal for effective drainage and filtration in fabric production. They provide excellent fluid flow and durability, essential for high-intensity operations.

Patterned conveying

Robust & accurate

Designed for stable and efficient transport of non-woven materials through production lines. Reinforced for added strength, suitable for high-speed processing.

Perforation

Innovative perforation technology

Utilized for creating precise perforation patterns in fabrics. They offer quick production with laser technology, which is essential for diverse manufacturing needs.

Why work with SPGPrints

The total package to meet your needs

As the ultimate specialist in rotary screen technology, we uniquely offer special screens for manufacturing and finishing hydroentangled nonwoven fabrics that will make you unique in your market.

We excel at manipulating the direction and shape of the nickel plating we apply to our rotary screens. As a result we can provide screens to meet any challenge. No matter how stringent or unusual your design requirements, with our technology there are no obstacles to stop you from meeting them.

A world of possible applications to be explored

Our technology offers countless possible applications to replace less efficient technologies currently used, in all kinds of market segments. To name an example, our expertise in applying and distributing perforations allows us to help ink toner manufacturers to achieve the required degree of precision filtration.

Add priceless value to your nonwoven product

During the hydro-entangling process you can add any desired pattern, no matter how complicated, to the fabric by embossing or perforation.

Just tell us what you need

We gladly challenge you take a look at your own process, think out of the box and tell us what you need. Chances are that we can provide you with a winning answer.

Other SPGPrints applications

We aim to bring colour to the world. Our experience, knowledge, understanding of businesses and true partnership have earned us many loyal customers.