How to arrange a digital textile printing process

Your first step into digital textile printing? Let this checklist full of steps help you to arrange the perfect digital textile printing process!

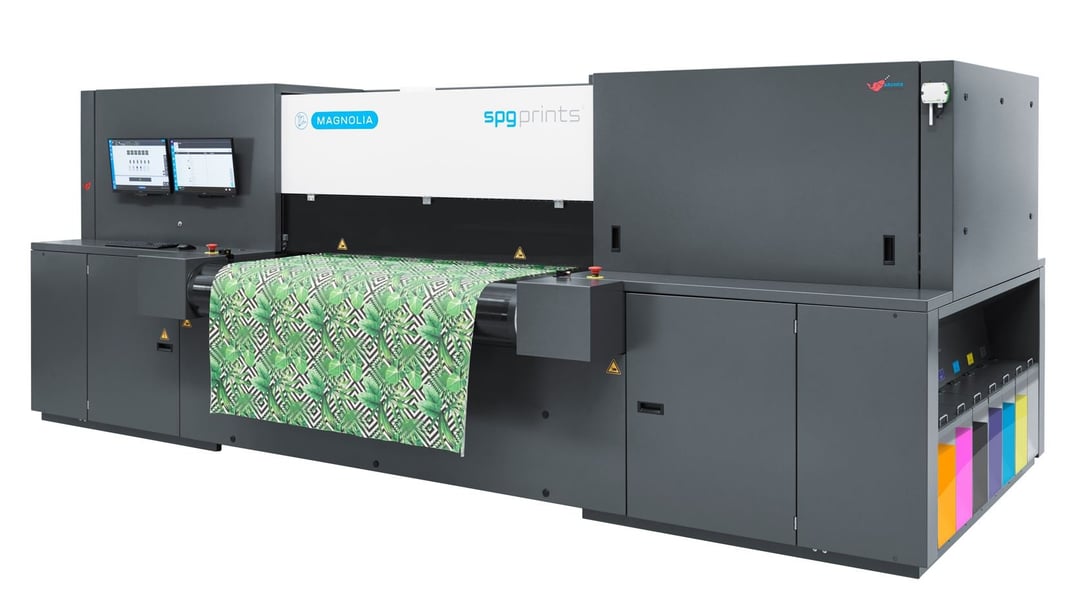

Read moreEverything is possible, Magnolia offers unsurpassed quality and value to textile printers who are taking the first step into digital production.

Printing Method

Scanning Inkjet Printer for Fabric

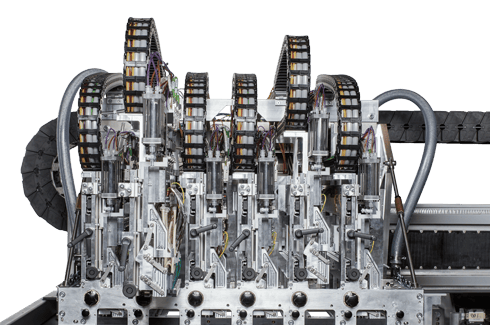

Print Heads

SPGPrints Archer+ technology with 36 FujiFilm Dimatix print heads

Print Head Gap

3-5 mm from substrate

Printing Width

1850 mm or 3200 mm

Print Resolution

up to true 1200 x 1200 dpi

Drop Size

2-10 picolitre variable drop size

Printing Speed

up to 550 m2/h

Inks

Reactive, Acid and Sublimation

Dryer

Horizontal dryer with 1/3 passages, up to 130°C, heated by gas or electric

Blotches, fine lines, geometric designs and intense colours can all be printed on a wide range of substrates.

Open creative possibilities with the wide range of substrates that can be printed by Magnolia: sublimation papers, natural fibres, lycra, wool, silk and even polyesters. Blotches, fine lines, geometric designs and intense colours can all be printed thanks to variable ink drop technology.

From infeed to outfeed Magnolia is designed to allow maximum freedom in choice of fabrics. Magnolia is a complete system, designed and engineered to make a complete solution. All elements are made to work together: print heads, inks, substrate conveyor, and dryer. However, within this system, there are options for ink (Reactive, Acid or Sublimation), and drying (gas or electric). With Magnolia from SPGPrints, configuring the right combination for your requirements is possible without compromising results.

With the development of the new Archer+ technology, we have created an adequate solution to one of the most pressing issues

for digital printing companies: the difficulty of delivering constant quality levels.

Besides delivering crisp, sharp and high-quality prints with unique details and high resolution, the new Acher+ technology is the first solution that enables automatic and operator-independent adjustment of each individual nozzle. Using the Archer+ technology, therefore, results in definitions and more uniformity.

In our Experience Center, you can witness the benefits of Magnolia with your own eyes. Will you visit us soon?

Our experts would like to share their knowledge and experiences with you.

Read all about inkjet technology in our blogs.

Every printing process is different and the same is true for the challenges you have. We’ve got you covered.

We aim to bring colour to the world. Our experience, knowledge, understanding of businesses and true partnership have earned us many loyal customers.