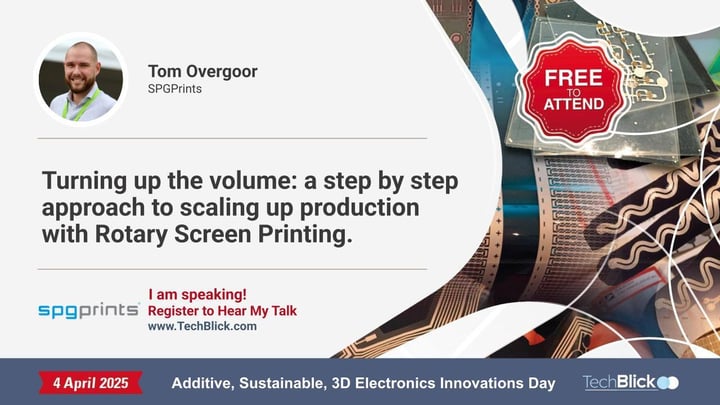

TechBlick Talk: Scaling Up Your Printed Electronics Production with Rotary Screen Printing Technology

Understanding Rotary Screen Printing Technology Rotary screen printing technology is a...

Read moreAs the Printed Electronics market is growing rapidly, the production has to keep up with the growing demand. This demand is caused by the increased use of Printed Electronics for smart devices, but also the development of sustainable energy and flexible Printed Circuit Boards.

There are several ways to adjust to this increased demand for Printed Electronics. For example, Rotary Screen Printing enables your printing process to print quicker and more efficiently (and save money along the way). The resolution and ability to print thick layers of ink, combined with the consistent quality produced by SPGPrints, make the screens ideally suited for the printing of electronics.

The Marble - RSI Unit is a self-contained single colour printing unit, available in

a choice of widths and incorporating intelligent control for problem free line synchronization. Designed to integrate onto your existing existing press, for the production of labels or other functional applications. You can either integrate directly onto your already installed press, or order a pre-integrated system.

As the Printed Electronics market grows rapidly, finding a scalable, high-quality production solution is essential. The Basalt RSI Line by SPGPrints is designed to meet this need. Offering rotary screen printing technology in an entry-level, Basalt enables businesses to scale up production efficiently, without compromising quality or breaking the bank.

If your Printed Electronics application has gone into series production, and the demand is rising, you could consider a full Granite production line. A well-thought design and software concept ensures that exchanging screens and squeegees is accomplished in minutes - minimizing downtime between jobs.

Printed electronics have incredible potential for multiple markets and user applications. Developing innovative products requires sophisticated manufacturing methods – and adopting new production processes involves risks, especially when these technologies and products are unproven.

This is where the Production-as-a-Service (PaaS) concept is a game changer. This whitepaper takes a deep-dive into this innovative concept. After reading, you'll know all about:

Printed electronics have incredible potential for multiple markets and user applications.

Companies across the world are developing innovative printed electronics products that require sophisticated manufacturing methods – but adopting new production processes or introducing

new machinery often entails significant financial investment. This exposes companies to risks, especially when these technologies and products are unproven.

Bridging the gap

This is where the Production-as-a-Service (PaaS) concept is a game changer. PaaS enables companies considering investing in high-throughput machines capable of producing printed electronics at an industrial scale to run small batches. At SPGPrints, we recently launched this new service to allow customers to learn about and try out new production options – offering them a risk-free option to trial new print technologies and experience the benefits before making an investment.

Explore new print production techniques

But PaaS is more than an outsourced printing solution. Customers are involved in every stage of the process, working with SPGPrints experts to learn the processes involved in printing electronics, explore the opportunities of new technologies and building an achievable roadmap to owning and operating an SPG rotary screen-printing machine in house.

Transitioning from etching to rotary screen printing can be challenging, but the benefits are significant. Success hinges on partnering with a company experienced in rotary screen printing, which can provide the necessary support and expertise. Engaging with production consultants ensures a smoother and faster adoption process, as they understand both the machinery and the operational adjustments required for a seamless transition.

Continuously optimize processes with an expert partner

SPGPrints leverages decades of expertise and innovation in rotary screen integration to help businesses smoothly transition to this technology. They offer global support, ensuring high-quality designs and efficient production setups, along with staff training. Whether investing in Basalt or Granite, clients benefit from SPGPrints' extensive experience and support for a stress-free transition.

The demand for (flexible) Printed Electronics is growing rapidly, and production has to keep up with this growth. In order to print quickly and efficiently, flexibility and the possibility to tailor your printing operations are important factors. This is what makes Rotary Screen Printing a perfect fit for Printed Electronics.

Printed Electronics Calculator

Take advantage of our latest innovation, the Rotary Screen Printing calculator. This tool allows you to determine the optimal timing for transitioning to Rotary Screen Printing and assess its benefits for your operations.

Reach out to our experts

If you have any questions about Rotary Screen Printing or integrating it to your specific Printed Electronics line, you can always contact our specialists. We’d love to hear your challenges and opportunities.

The global printed electronics sector is ready to scale-up. And that means identifying and investing in the most suitable technology. The biggest challenge when scaling up is ensuring quality and consistency of your outputs. Explore how to effectively transition from lab-scale to industrial-scale equipment with the insights provided in our Market Guide!

Our experts would like to share their knowledge and experiences with you. Read all about Industrial Printing and the benefits for your company in our blogs.

We aim to bring colour to the world. Our experience, knowledge, understanding of businesses and true partnership have earned us many loyal customers.