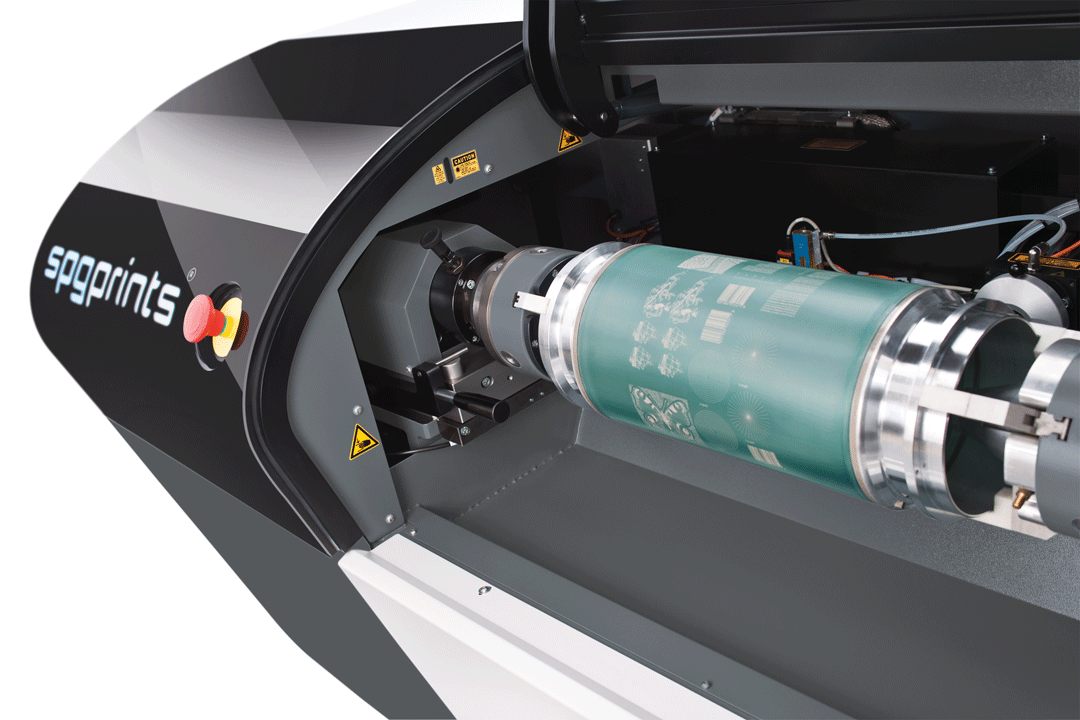

PLATINUM. Higher relief depths for sleeves, roller and plate on drum.

The PLATINUM is designed for seamless elastomer sleeves or plates, especially in the flexo industry. Printers can now produce the highest quality print with a shorter, solvent-free process, by longer runs and multiple cost saving potentials in the printing process.

At a glance

- Highest quality with longer runs

due to Active 3D® dot shaping and below surface dot - Solvent-free & shorter process: single step dry process

- Sealed CO2 or fibre laser:

C02 laser available for all printform colours - Deep seamless relief engraving

- Remote service control

Surface scan > engraving > milling > hoovering in one sequence

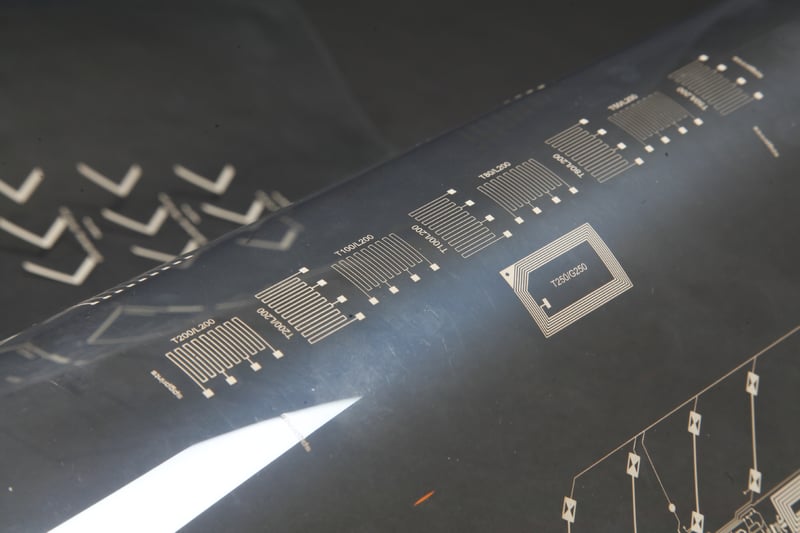

The PLATINUM (formerly KRONOS) offers eco-friendly direct laser engraving (DLE) technology, free from solvents. It achieves top-quality results even at greater relief depths, meeting current and future elastomer sleeve requirements. Our in-house Active 3D®-RIP system customizes dot shaping for stable highlight dots during extended print runs. Below-surface dots eliminate dot gain. The PLATINUM features a digital database for storing calibrated material specifications, reducing human errors and improving workflow efficiency. Designed to work with air cylinders or an optional precision quick exchange system, it also offers ‘Auto Milling’ for increased productivity and ‘Scan & Calibrate’ for advanced quality through semi-automated material calibration.

Watch our video!

Useful facts about PLATINUM

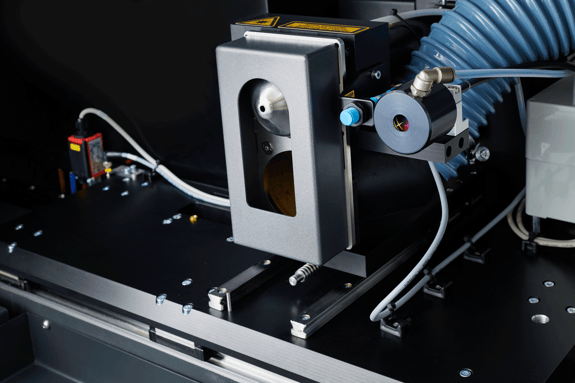

Laser

- sealed CO2 laser

- fibre laser

Resolution

variable up to <5.080 dpi

Sleeve repeat size

125 - 1.250 mm / 4.95“ - 49.45“

Sleeve engraving width

- < 2.000 mm / 79“

- < 3.200 mm / 126“

Dimension machine LxWxH

- 5580 x 1955 x 1460 mm

- 6780 x 1955 x 1460 mm

Load weight up to

1000 kg

"The PLATINUM is a high quality workhorse for deep seamless relief engraving of heavy cylinders & plates”.

OPTIONAL AVAILABLE ACCESSORIES

• Scan & Calibrate

sleeve surface measuring for quality check and semi-automated material calibration

• Rapid removing

milling of non-printing areas

• Various toolings

magnetic & vacuum drum for plate-on-drum applications

• Precision quick exchange system

as optional mounting system

.png?width=900&name=PLATINUM%20three%20jaw%20juck%20(KRONOS%208612%20F-11).png)

.png?width=900&name=PLATINUM%20(KRONOS%208612%20F-09).png)

Chemical-free approach enhances sustainability

The system employs a unique single-step dry process to eliminate non-printing areas by simply burning away the polymer. There is no need to handle or store chemicals. After engraving, the customer doesn’t need to further process the print form or take any additional steps.

Lower operational costs

A perfectly coordinated software (in-house developed CAD/CAM) and hardware achieves streamlining workflows, reducing process steps, and allowing multiple print forms to be used on a single machine. Additionally, the PLATINUM is available as sealed CO2 or fibre laser. The sealed CO2 laser is available for all printform colours. Achieve longer runs due to Active 3D-RIP system and engraving of seamless sleeves which offer more durability - with PLATINUM Direct laser engraver.

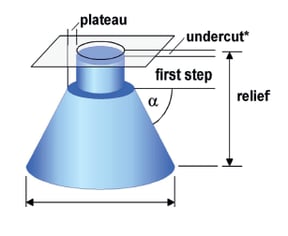

Stable highlight dots with customized dot shaping: Active 3D RIP system

A unique Active 3D®-RIP system, developed in-house, enables three-dimensional dot shaping for printing forms. This innovative approach prevents over-impression of smaller elements by positioning them below the printing surface, ensuring they print consistently alongside larger elements, resulting in exceptionally fine results with extreme accuracy and repeatability.

Discover all pre-press systems for industrial applications

Many different applications can be supported with SPGPrints pre-press systems:

Check our industrial pre-press solutions here

Read more insights on industrial printing solutions

Our experts would like to share their knowledge and experiences with you.

Read all about industrial applications in our blogs.

We aim to bring colour to the world. Our experience, knowledge, understanding of businesses and true partnership have earned us many loyal customers.