Unlocking the Secrets of Rotary Screen Printing: 8 Key Insights for Industrial Applications

1. Revolutionary Technology Introduced by SPGPrints in 1988 SPGPrints is a leading innovator in the...

Read moreThe dynamic market and the ongoing technological developments force the printing industry to increase the quality and improve the flexibility in file formats, materials and printing technologies. The TITANIUM, formerly variLEX, is SPGPrints‘ answer to the need of a multifunctional CTP solution.

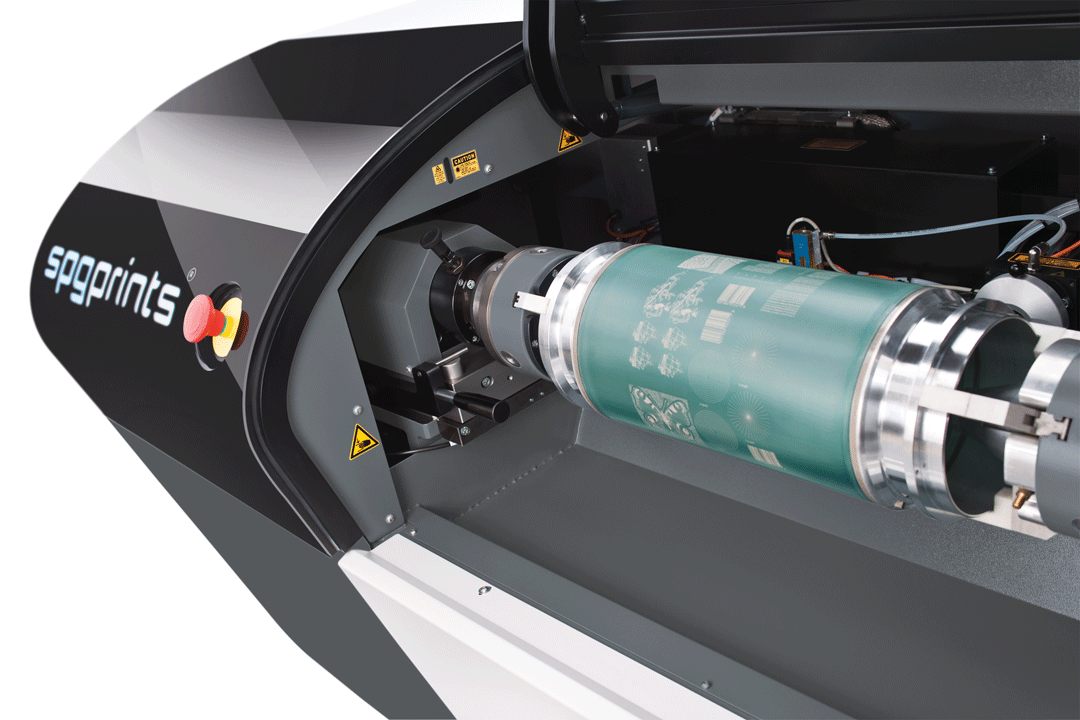

“The TITANIUM, equipped with a multi-beam fiber diode laser system, offers improved quality and flexibility for the printing industry. It can ablate black masks and directly expose UV-sensitive materials. The unique inline UV LED exposure system eliminates offline main exposure. The machine handles various materials using different mounting cylinders. SPGPrints’ software solution ensures compatibility with common file formats, making the TITANIUM the most flexible pre-press solution for labels and packaging.”

Laser

FD / UV multibeam

Resolution

HD standard 5.080 dpi

Max. plate size

Max. number of plates

RotaPlate size

10“-25“ x 555 mm

CTP - Computer to plate solution / max. plate size 25" x 30"

"Most flexible, high quality pre-press solution for the label and packaging industry.”

CTP - Computer to plate solution / max. plate size 48" x 35"

"Most flexible, high quality pre-press solution for the label and packaging industry.”

The machine can be equipped with different mounting cylinders to handle different materials:

.png?width=900&name=TITANIUM%20detail%20(variLEX-7).png)

.png?width=900&name=TITANIUM%20(variLEX-066).png)

A perfectly coordinated software (in-house developed CAD/CAM) and hardware achieves streamlining workflows, reducing process steps, and allowing multiple print forms to be used on a single machine.

Fiber diode lasers are employed for imaging the printing form by either ablating a black mask or directly curing a photosensitive lacquer using UV lasers. Depending on your specific requirements, the laser head can be delivered in various configurations to match your productivity and flexibility needs. Our laser diodes are combined with high-definition optics, ensuring they meet even the most stringent quality standards. Additionally, our system features an integrated inline UV LED exposure system, significantly enhancing print quality by creating sharp shoulders and flat-top dots. Compared to other UV techniques on the market, this approach allows for cleaner printing results and a broader tonal range. Beyond quality improvements, our inline UV process streamlines production, enhances reproducibility, and reduces labor. All you need, in addition to our CTP system, is a power socket and a plate washer.

.png?width=1080&name=mineral-2382040%20(1).png)

Many different applications can be supported with SPGPrints pre-press systems:

Check our industrial pre-press solutions here

Our experts would like to share their knowledge and experiences with you.

Read all about industrial applications in our blogs.

We aim to bring colour to the world. Our experience, knowledge, understanding of businesses and true partnership have earned us many loyal customers.